About ORGANIC

ORGANIC aims to boost the biological transformation of Additive Manufacturing (AM) processes by integrating bio-design, bio-based materials and bio-intelligent manufacturing into Fused Granulate Fabrication (FGF).

ORGANIC unites dedicated minds from 13 organisations in this quest, funded by the European Union.

Why revolutionise additive manufacturing?

3D printing has already shown its value: it reduces CO₂ emissions, saves resources and helps design smarter products.

In ORGANIC, we move beyond the current benefits. We asked ourselves: What if additive manufacturing followed principles derived from nature to make it even better than it is already?

That’s our goal: to bring biology into additive manufacturing and create smart systems that don’t just make products, but also adapt, learn and improve.

Biocomposites as a starting point

Our first step is simple but powerful: printing with biocomposites. These natural, fibre-reinforced materials let us create fully recyclable lattice structures that are both lightweight and durable just like those we see in nature.

From there, we’ll go further. We will develop a printing systems that can self-configure, self-monitor, self-optimise and even self-heal. Real-time data and artificial intelligence will serve as enablers.

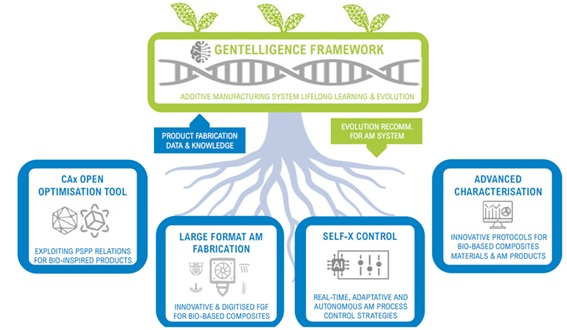

With this, we will set up a gentelligence framework for additive manufacturing

Our approach

Gentelligent Additive Manufacturing (AM) framework

Gentelligence links design, production and quality data through semantic digital twins and AI-powered knowledge graphs, enabling self-adaptive, zero-defect and sustainable production.

From first-time-right manufacturing to bio-inspired materials, it drives smarter, flexible and future-ready factories.

Open CAx: Optimising bio-inspired lattice structures

A single, integrated workflow that links design, toolpath and process planning will enable efficient creation of bio-inspired lattice structures. The approach enhances structural performance while reducing weight and material use, resulting in strong, lightweight and sustainable components.

AI-driven tools predict material behaviour and performance, providing precise control over each parameter to ensure every design meets its intended function.

Advanced FGF printing for bio-based composites

A large-format Fused Granulate Fabrication (FGF) system will enable the production of high-performance components from bio-based materials.

Precision-controlled extrusion, real-time monitoring and advanced thermal management deliver strong, lightweight and sustainable parts, optimised at the fibre level.

Self-X AM control

Traditional AM struggles with real-time variations, often causing defects — especially with bio-based materials. We are about to change this with a self-X adaptive control system that predicts, optimises and corrects in real time.

Its AI-driven, self-monitoring, self-healing framework ensures higher reliability, repeatability and quality, transforming complex bio-composite printing while boosting efficiency and sustainability.

Large-scale bio-inspired manufacturing

Building complex, bio-inspired structures at large scale is a major challenge in additive manufacturing. Material variability, process stability and structural integrity often limit performance — especially with bio-based composites.

We tackle this by combining advanced fibre-reinforced materials, self-adaptive AM systems and AI-driven design optimisation.

Draft

The big picture

This approach is driving the future of large-scale, bio-intelligent manufacturing.

With ORGANIC, we’re not just improving additive manufacturing.

We’re transforming it into a living, learning process.